Article Summary

- Printer productivity cannot only be measured by printing speed. Effective productivity is important.

- Maintain the printhead discharge status to reduce pre-printing.

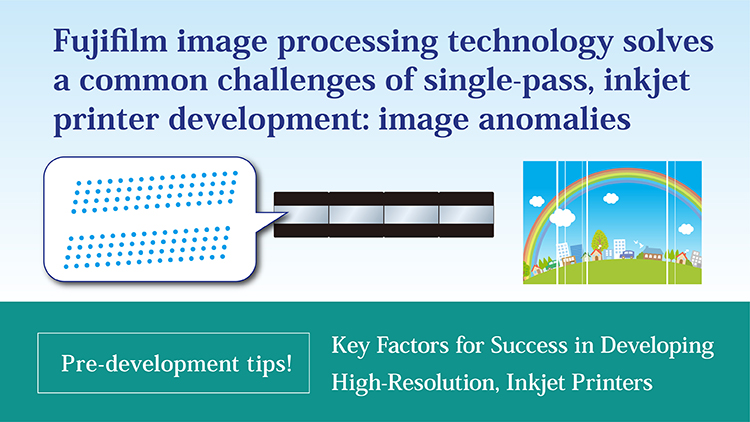

- Detect print non-conformities and correct images to reduce extra print adjustment and inspection time.

Printing speed is essential to organizations that purchase a printer but print speed and print productivity are not the same. To develop a highly-productive printing system, users must consider preparation time, both the time required for press calibration and adjustments, and the time needed to inspect the final printed pages.

Build Your Printing System for High Productivity

Consider these three ways to increase the productivity of your printing system:

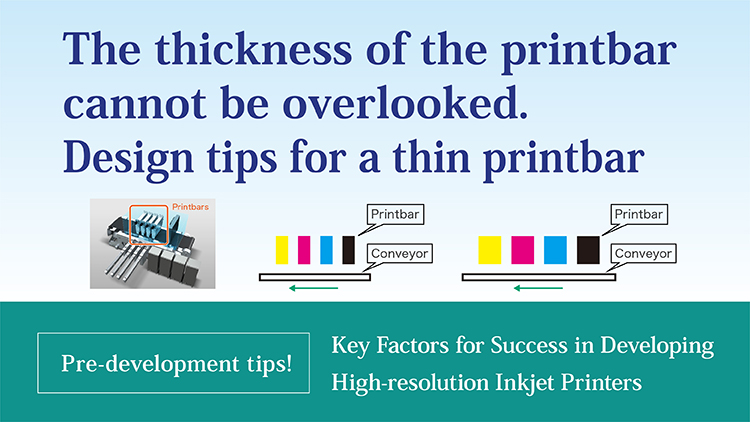

- Reduce printing set-up time

- Reduce printing adjustment & calibration time

- Reduce print quality inspection time, including re-printing

Printing speed is not the only factor when developing a production printing platform. The productivity of the platform determines the true value to the buyer. To find the productivity of the system, look for the adjacent activities that occur around the press for key performance indicators (KPI).

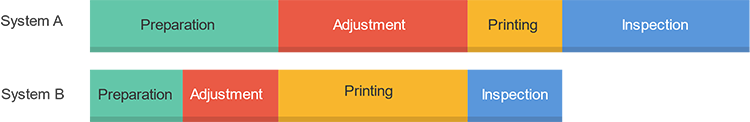

Consider the hypothetical example of two printing systems, A and B, where A is twice the speed of B. It might seem that printer A would have the advantage, but that may not be true. If printer A takes twice as much non-printing time, printer B may be the preferred solution. That non-printing time may include job set-up, printer calibration and adjustment, and inspection. The chart below shows how these factors can change press productivity.

Although printing system A has a faster printing speed, the non-printing elements take more time.

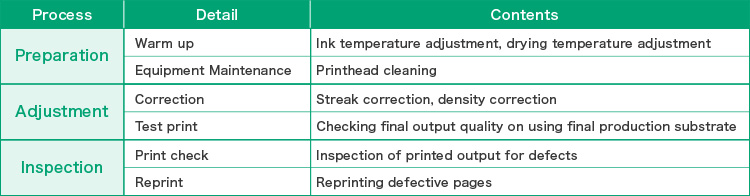

To understand how these non-printing processes impact the total print productivity, consider the time it takes for each non-printing activity.

Table 1 Inkjet printing systems operations other than production printing

These non-printing tasks are essential to the operation of the printer, so it is important to reduce the amount of time spent on these tasks to maximize overall printing productivity.