Exclusive: Fujifilm shares tips for high-resolution inkjet printer development amassed through commercialization of the FUJIFILM JET PRESS (also commercially available as J PRESS in the U.S.) 1,200 x 1,200 dpi, single-pass inkjet printer.

Summary of the article

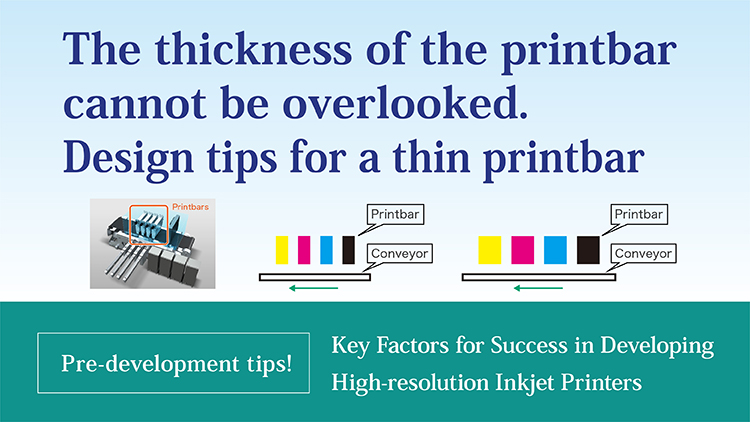

- A thin printbar reduces the size and the manufacturing cost of the machine, as well as preventing color misalignment.

- Three factors to make a thin printbar are (1) size of printhead, (2) design of the Ink circulation system, and (3) drive frequency of the printhead driver board.

- The arrangement of ink circulation system in the printbar and with respect to the heat dissipation of the printhead driver board, are each very important.

What is the problem with thick printbars?

When printing with multiple colors, multiple printbars are aligned in the feeding direction. If the printbars are thick, the following problems may occur.

❶ Increase in size of printer

For single-pass inkjet printers, the distance required to print is determined by the following formula.

(Printbar thickness + Arrangement interval between printbars) x Number of colors

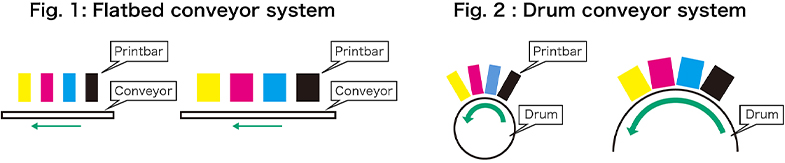

Thick printbars can require a larger printer housing. For example, in the case of the flatbed conveyor system, the thicker the printbar, the longer the printer length will need to be (Fig. 1).

Likewise, in the case of the drum conveyor system, the thicker the printbar, the larger the required drum diameter and printer height (Fig. 2). A larger drum diameter size can increase the manufacturing cost of the printer by up to USD $10,000 per drum, depending on its size.

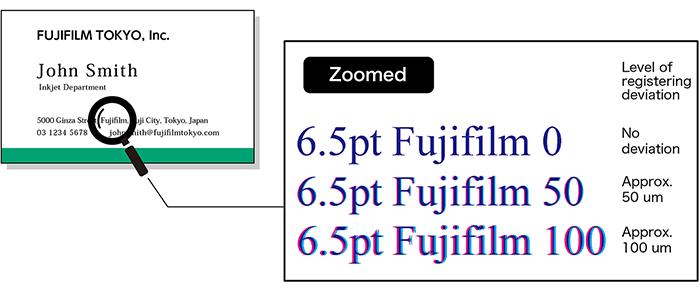

❷ Deterioration in color registration accuracy

The larger the distance between printbars, the greater the effect of web weave, which is the tendency of the web (e.g., paper) to move back and forth in a direction perpendicular to the intended printing direction, resulting in inaccurate color registration . For example, if 5-color printbars each with a thickness of 20 cm are lined up, the length required for printing will be greater than 1 meter. It is difficult to maintain conveying accuracy within several dozen microns over this length. Registration shifts of as much as 100 microns are common in this situation.