When developing a high-speed inkjet printer, decisions made during development directly influence print quality and print speed. The target application is a determining factor. For example, applications such as transaction documents, graphic arts brochures, and photo-realistic prints each have different requirements in terms of the amount of ink needed for laydown , drop size, drop density, and drop uniformity to achieve the desired effect. A clear understanding of target applications is required before system design begins.

To create a specification for the intended print product, identify the following variables:

- What are the target applications?

There may be more than one, so consider the target application with the most exacting requirements. In some cases, the needs of various applications are met by changing the print speed. This can work as long as the overall system meets the end user requirements for the broadest set of applications. - What is the target print quality?

Consider the nature of the target application in order to determine the level of ink density necessary to meet color gamut, consistency, and uniformity. Transaction print may use four-color CYMK ink, but the ink density requirements may be secondary in importance to print speed. Graphic arts and photo applications may require deep color gamut and density with less sensitivity to speed. - What are the other constraints for the printing system?

There are speed versus quality trade-off decisions for many aspects of your design, including the transport. Typically, faster speeds require a more robust transport and carry specific requirements for drying and curing needed to maintain product quality. Review your constraints while configuring the printheads to ensure that system performance requirements can be met.

The diligence you put into developing your specifications will solidify the printhead specifications required to meet your needs. This article provides information on these key elements of your development plan.

Determining printing system speed depends on many factors.

Only one is directly related to printhead specifications.

Print output specifications are based on the needs of the target market. While planning development of a new product, it is tempting to make a selection based solely on the printhead specifications. However, using only the printhead resolution and the maximum drive frequency to make decisions may result in a system that does not meet the desired output quality for the targeted applications. To illustrate, review this example:

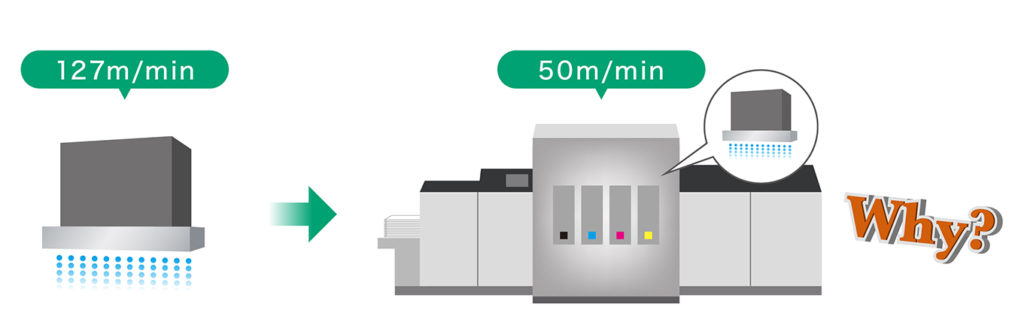

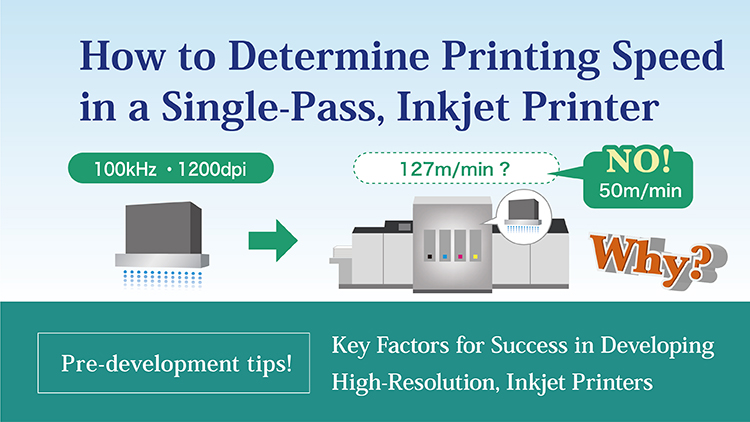

Consider a single-pass inkjet printer with 1200dpi 100 kHz of printhead.

A simple calculation shows that the theoretical speed this printhead can reach is 127 meters per minute or 1 inch/1200 ×100 kHz = 127 m/min.

However, among high-resolution 1200x1200 dpi inkjet printers with a printing speed of 127 m/min or greater, most are configured with multiple parallel print heads to achieve high speed rather than using a single row of printheads.

Why are printhead specifications not the only determinant of print speed? To find out, let's take a look at what factors are used to determine printing speed (Fig. 1).