One of the questions inkjet printing solution integrators commonly ask is related to printhead life. The time span from installation to the time the printhead can no longer print with the required quality, has a direct impact on the total cost of operation, maintenance scheduling, and budgeting for replacement parts.

Extending the life of a printhead has a direct financial impact on the cost of print since large industrial inkjet printing systems may be equipped with many printheads. The longer printheads are in use, the lower the operating costs of the system, which has a positive impact on profitability as printhead life amortization occurs over greater print volume. Longer printhead life also reduces time spent on diagnostics and maintenance of printheads that have reached end-of-life.

The factors impacting the life of a printhead, beside its fundamental design, include items such as ink type in use, as routine cleaning methods and processes. Cleaning methods and processes play a significant role in maintaining printhead life. We covered printhead-cleaning processes in a separate article that was posted to our website.

In this article, we examine the strategies a system integrator can use to understand printhead life within their product. These strategies are vital for developing standard maintenance procedures and processes that can indicate to end users when a printhead change is required for maintaining high print quality and productivity.

Developing a printhead evaluation process

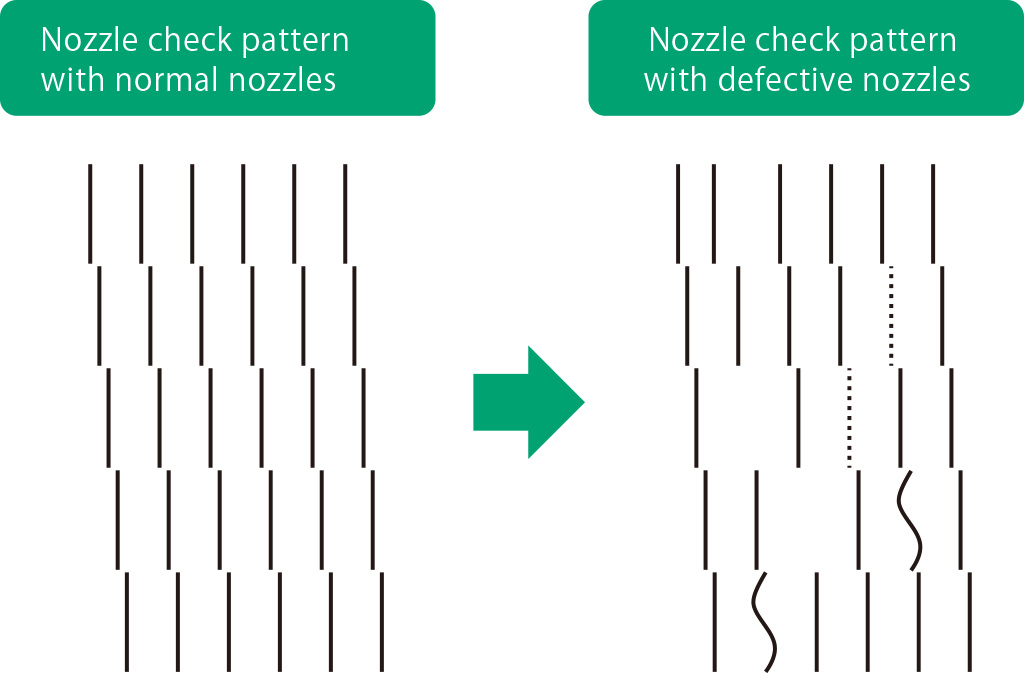

As printhead components reach their designed end of life, nozzle deterioration is commonplace; it has direct impact on output quality. Over time, nozzle deterioration will have an adverse impact on the way the ink is ejected. When a new printhead is installed, the number of defective nozzles is minimal or zero, however, as the printer is used in production the number of defective nozzles tends to increase and eventually will produce undesirable print defects such as streaks and banding. At the point, where print output quality becomes unacceptable the printhead will need to be replaced.

To estimate when a printhead needs to be replaced, Fujifilm has developed a quantitative printhead life analysis method based on assessing thousands of printheads. Our experience with this analysis process is the basis for the printhead life estimating process detailed below.