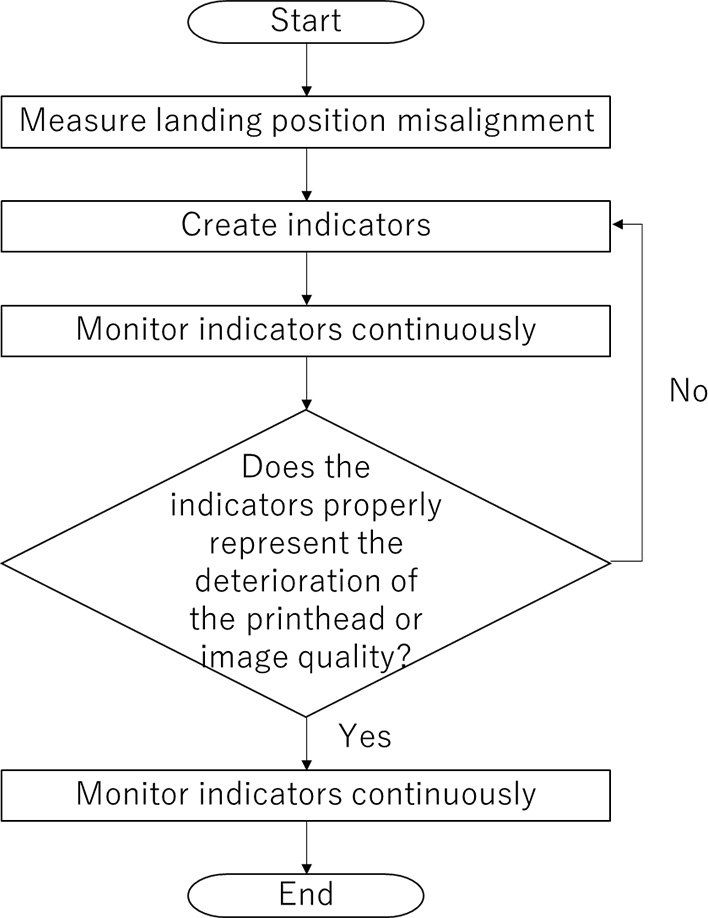

Three steps for assessing printhead

Fujifilm has identified three steps that enable quality estimations of printhead life.

Review each step as you develop your plan for estimating printhead life in the context of your integration.

1. Measure landing position misalignment

Landing position misalignment is determined by measuring the difference between where the droplet should land and the actual landing position. To take the measurement, construct a test process that identifies where droplets should land, and where they finally land on the substrate. Record the information for use in the next step.

2. Create indicators

Typically, the standard deviation (σ) of the landing position for each nozzle in one printhead is used as an indicator of the landing performance of the printhead. However, there are additional indicators that can be used as printhead life indicators.

Landing position indicator:

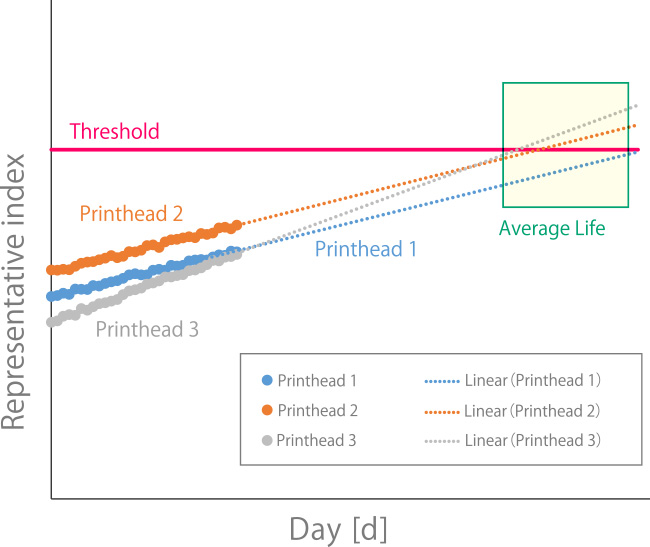

The amount misalignment in the landing position is an index, referred to as the representative index. It correlates with printhead life. For example, σ may be a representative indicator if σ is highly correlated with the life of the printhead. When a deviation becomes visible, indicated by noticeable streaks and banding, capture the time since the installation of the print head. The time between installation and the deviation becomes an indicator that is marked on a chart. Continuous monitoring and charting this indicator is used for printhead life estimation.

If σ does not correlate significantly with printhead life, other indicators can be used. These may include:

- Standard deviation of landing position.

- Number of bad jets (miss jets)

- Distance between bad jets

- Drop volume

- Drop speed (Jetting speed)

This is not an exhaustive list of possibilities. Review your system specification for other options.

The Fujifilm team is available for consultation and additional support in developing your strategy for printhead life assessment.

3. Monitor indicators continuously

Once a process to capture indicators is in place, identify the number of printheads to be monitored under the same conditions for a defined period to obtain data on how much the representative indicator changes. In this article, the selected indicator for tracking is drop-landing position. To obtain tracking data that can provide printhead life indicators continuously, measure the amount of landing position misalignment and record the value of the representative index daily.

It is important to maintain daily measurements of representative indicators under the same conditions.

For example, take measurements at the start of operations each morning, use the same type of printing media (value may vary based on the substrate and cause noise in the indicators), and perform the same routine maintenance base on you recommended maintenance process.

It is also necessary to keep the environmental conditions constant, these include items such as ink type used, the jetting distance from the nozzle to the printing media (standoff), the head cleaning method, drying conditions after printing and relative humidity in the room.

Using the data obtained as defined above, plot the changes for each printhead on a graph to show the relationship between the number of days and the representative index. Then, extrapolate the average life of the printhead, which is defined as the period in which the representative index deteriorates and reaches the threshold. For advanced production printing systems it is advisable to develop an automated solution that can capture this information, add it to a database, and create both an internal assessment tool as well as a client-facing access tool. This will add value to your solution and instill confidence in your customer relative to their expectation of performance by your solution.

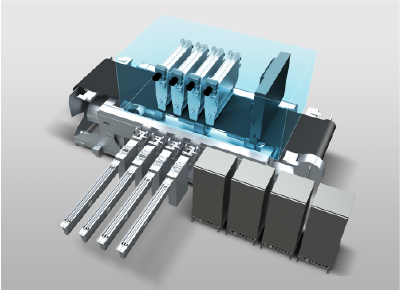

FUJIFILM SAMBA JPC® encompasses the building blocks that enable developers to streamline the development of as productive high quality solutions with the components needed for tracking system performance and productivity.

If you have any questions or concerns about development, please feel free to contact us using the form below.

FUJIFILM SAMBA® JPC: A set of inkjet components revolutionizing the speed of 1,200 dpi, high-resolution digital printer development.