Using image inspection to improve image quality

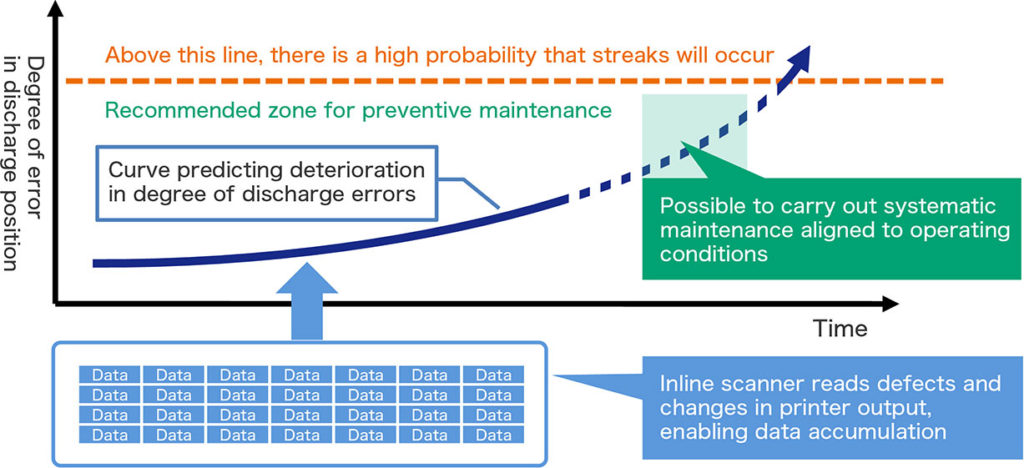

Incorporate an image inspection camera or scanner for print output into the system to capture information on the status of the hundreds of thousands of nozzles in real time. To augment the inspection, develop resolution protocols designed to help eliminate these artifacts.

For example, by changing the settings for the jetting pressure, speed, and other factors based on analysis of the inspection results, adjustments manual or automatic systems can address and minimize image defects so these less likely to occur. This allows the imaging inspection process to contribute to the design of the key elements of the system, including the material used, the inks, and the equipment, such as head-cleaning devices.

The inspection system can also acquire image data in real time to identify the state of the printhead based on the printed output. That data can also be used to predict when anomalies, such as jet straightness, deviate from the baseline reference. Using this data, the system developer can formulate a plan for predictive printhead maintenance, ensuring efficient printer operation with minimal risk and expense.

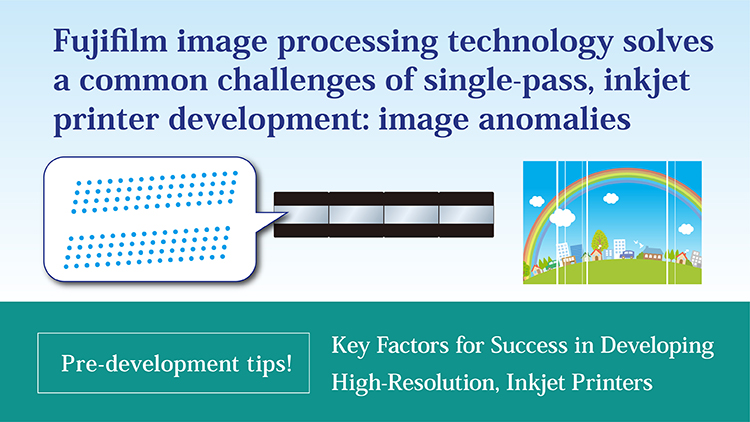

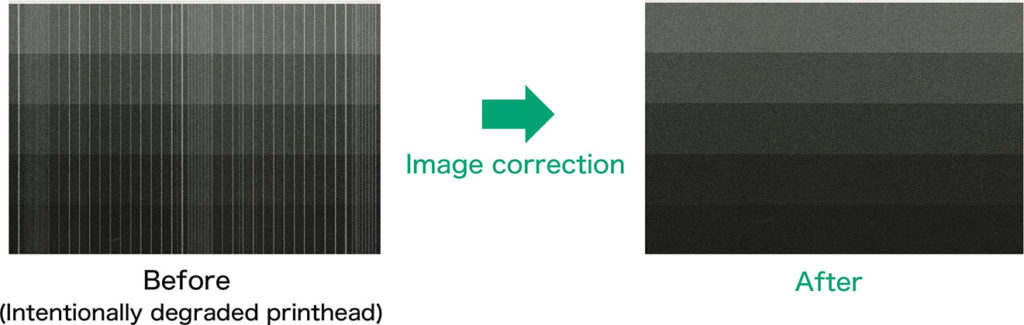

Image compensation for anomalies due to deteriorating nozzle straightness

Once captured by an inline scanner, the resulting images are transferred to the printer controller for further processing. In this stage, the captured data is analyzed and corrective action is applied. There are many possible image compensation techniques, but most are applied by adjusting the original image data based on the anomaly analysis provided.

In the image above, streaks have been introduced in the image to demonstrate the appearance of undesirable anomalies. No corrective measures have been applied to fix the nozzles, but image compensation algorithms have been applied to the streaked image, resulting in corrected higher quality print output. This technique is valuable in high-resolution, single-pass inkjet printers due to the number of nozzles in use while the print bar is jetting on media that moves in a linear direction.

Advanced image detection and compensation techniques, data analysis techniques, and operational experience make up the recipe for turning the results of image inspections into device design improvements. The best implementations can reliably eradicate image anomalies.

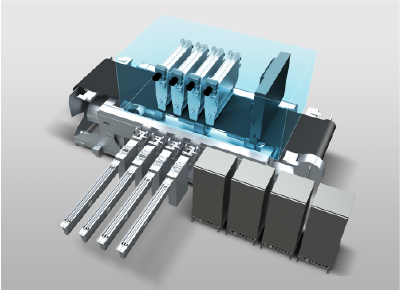

FUJIFLM SAMBA JPC® inkjet components can be incredibly helpful to high-resolution, single-pass inkjet printer developers wishing to capitalize on Fujifilm's extensive development experience and knowledge base. Certain components of the FUJIFILM SAMBA JPC product are designed to address image anomalies in a consistent and seamless manner when integrated into a single-pass system design.

Use our knowledge, techniques and FUJIFILM SAMBA® JPC modules, to make your development process more efficient, predictable and to support your commercialization timeline. As a leader in printing digitization, let Fujifilm help you contribute to the expansion and development of the inkjet market.

FUJIFILM SAMBA® JPC: A set of inkjet components revolutionizing the speed of 1,200 dpi, high-resolution digital printer development.