Fujifilm has some of the best printing technologists in the worl d. Many problems were solved when developing the FUJIFILM JET PRESS (also commer cially available as J PRESS in the U.S.) 1,200 x 1,200 dpi high-resolution, shee t-fed single-pass, inkjet printer. Let our experience be for your benefit.

Summary of the article

- Streaks and banding are major technical challenges for development of high-resolution single-pass, inkjet printers.

- Streaks and banding can be caused by many factors, necessitating systematic understanding and analysis.

- Identifying trends in streaks and banding, and measures to deal with them, enhances the efficiency of inkjet printer development.

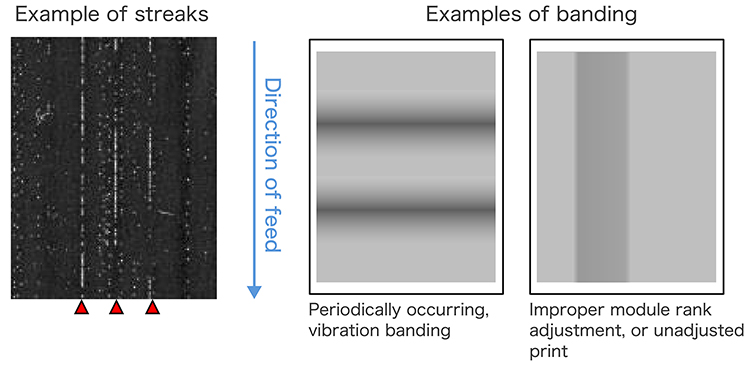

Streaks and banding are typical image defects that can occur as single-pass inkjet printers age (see illustrations below). These defects occurred frequently in the early stages of Fujifilm's development of the FUJIFILM JET PRESS, and significant engineering resources were spent addressing these major issues duri ng development. The challenge is especially daunting in high-resolution printers configured for maximum image quality even with perfect printheads because dots are generally small and fine streaks tend to be visible.

For example, for photo-quality images, damage to a single nozzle can produce a visibly poor impact position. The cause of such damage needs to be identified and appropriate measures taken, but causes can range from degradation over time to nozzle damage due to wiping during maintenance. Streaks can occur even when discharge positioning is correct, such as streaks caused by scratches when substrate is fed into the printer. The same applies to banding. To enable our readers to swiftly deal with the occurrence of streaks and banding and to efficiently proceed with printer development, this series outlines a systematic approach to determining the causes of streaks and banding, and provides examples of measures desig ned to prevent them.

First, gather comprehensive information. Streaks and banding happen on site!

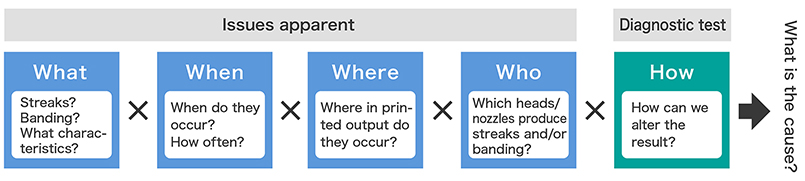

When considering measures to address streaks and banding, it is primarily important to gather plenty of information about the circumstances under which they are occurring. By analyzing this information, bearing in mind the “what, when, where, who, and how” approach illustrated below, the causes of streaks and banding can be identifiedand understood.

It is important to comprehensively gather information. In inkjet printer development, seemingly unrelated phenomena can sometimes be the dominant fac tor. Jumping straight to thinking about "What is the cause?" can narrow the perspective and cause the dominant factor to be overlooked. Fujifilm's printing techn ologists often faced quality issues relating to streaks and banding in developing its acclaimed JET PRESS products, and this experience underscored the overwhelming importance of accurate information gathering.