Fujifilm offers critical print system components to integrators and OEM manufacturers of inkjet printing systems with FUJIFILM SAMBA® JPC products. Based on Fujifilm’s SAMBA® printhead core technology, these include a set of modules that allow inkjet printing solution integrators and manufacturers to leverage Fujifilm’s expertise in inkjet printers and to facilitate development and compress time to market.

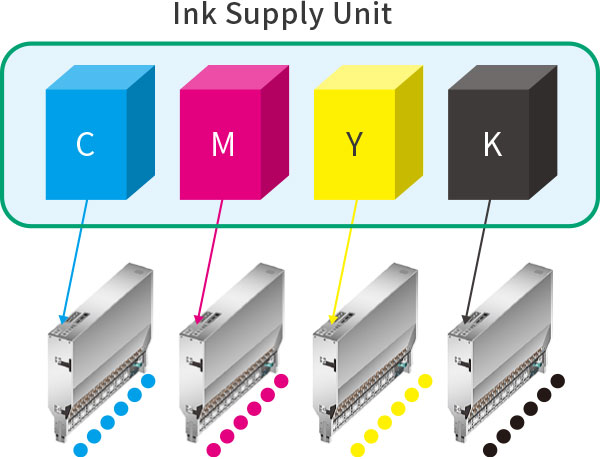

Previous articles in this series have focused on the control of print quality, especially streaking and banding. We reviewed the importance of cleaning the printhead, controlling printhead vibration, and managing the Inline Scanning (ILS) system to control print anomalies. In addition to determining the source of anomalies, prior articles also discussed mitigation strategies and remedies. There is also one more component to consider that can influence output quality: a stable ink supply. An unstable flow of ink to the printbar and printheads is a potential source of streaking and banding.

In this article, we review four ways that ink supply can affect print anomalies:

- Foreign matter in the ink.

- Air bubbles.

- Ink temperature.

- Control of the meniscus.

From diagnosis to countermeasures, review these steps to ensure that your ink supply will meet your production needs.

Build the ink supply system to meet your product performance specifications

A streaking and banding diagnosis sometimes points to printhead deterioration; however, the actual culprit may be the ink supply system. When these anomalies begin after months or years of trouble-free, high-quality printing, or emerge after printing hundreds or thousands of pages, the root cause may be an unstable ink supply. The lack of stability can be the result of foreign matter or air bubbles in the ink, poor control of ink temperature, and problems controlling the meniscus. Addressing these issues can restore print quality without replacing printheads.

The following sections address the procedures to diagnose streaking and banding caused by ink supply problems and guidance on how to resolve them:

- Removal of foreign matter and suppression of foreign matter generation.

- Countermeasures against air bubbles.

- Control of ink temperature.

- Control of meniscus in nozzles.