What are the functions of a printhead capping unit?

The following are the key functions of a printhead capping unit:

- Preventing the printhead from drying.

- Preventing condensation on the printhead.

- To capture ink that is jetted during a purging cycle.

The first and third functions are easy to recognize, but condensation on the printhead is often overlooked as a cause of print anomalies. We review below each functionality with suggestions for how to remedy print artifacts.

Case 1: Preventing the Printhead from drying.

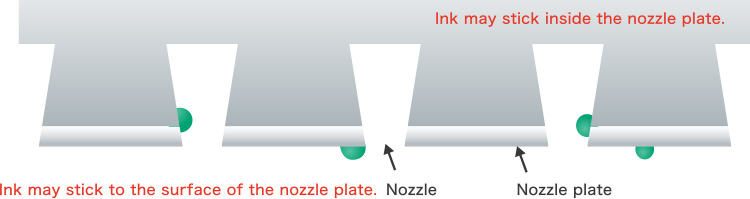

In inkjet printers, it is common for some ink or ink mist to dry on the nozzles. Streaks may occur in print output due to the deterioration of jetting conditions (Fig. 2). This can happen when the printhead cap is not airtight.

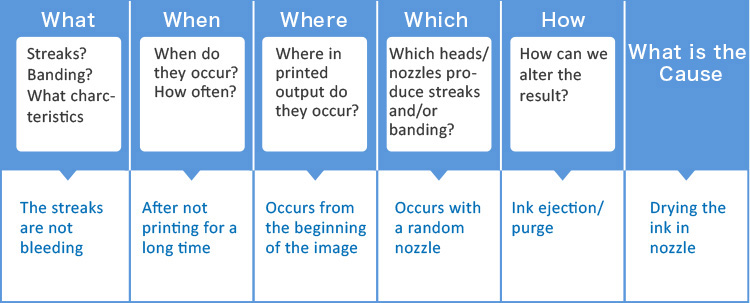

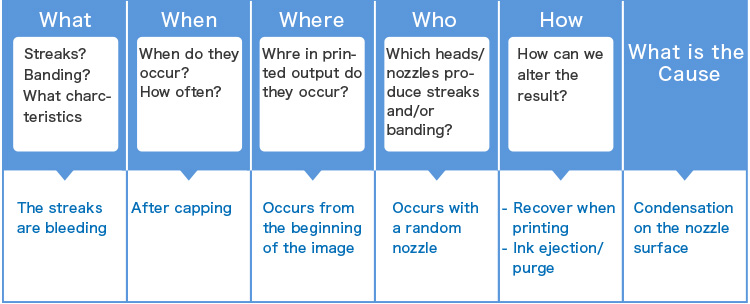

Examples of streaks caused by ink drying are summarized as shown in Table 1 below. This information is similar to the first article where we reviewed the topic.

Table 1. Example of streaks caused by ink drying

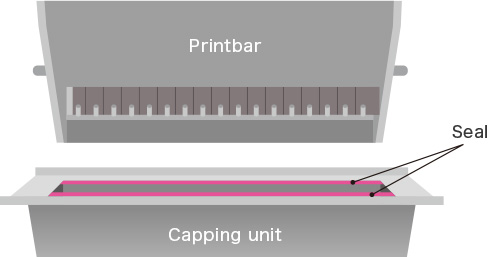

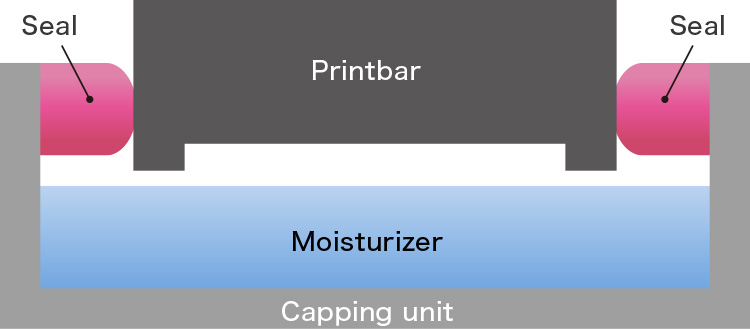

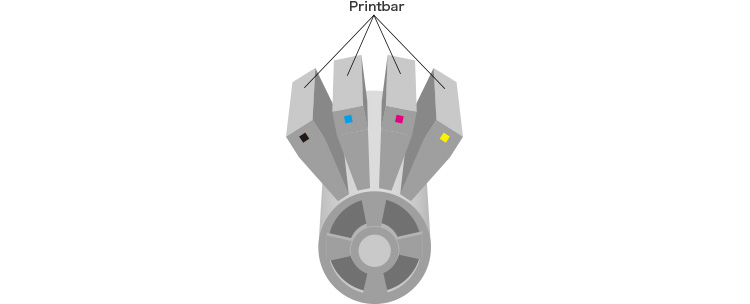

The key to creating an airtight environment is to ensure that there is a seal between the capping unit and the printbar. (Fig. 3, Fig. 4).

The seal plays a role in preventing the moisture from evaporating through the gap between the printhead and the capping unit, which lowers the moisture near the printhead causing the ink to dry. A gap between printhead and the capping unit may be caused by:

- Assembly error/distortion of cap parts

- Dimensional irregularities in the printbar

- Adhesion of ink contaminants to the capping unit seal

If the capping unit seal is pressed too hard against the printbar so that there is no gap, it may cause the printhead position to shift. Using a high-definition printhead, such as 1200 dpi, can particularly cause misalignment between colors and streaks.

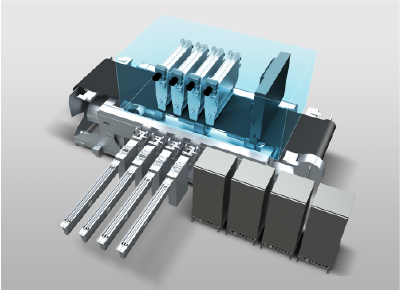

To properly maintain humidity levels, it is essential that the seal is designed to ensure airtightness between the printhead and capping unit and to prevent against displacement of the printhead. One of the FUJIFILM SAMBA® JET PRESS Components (JPC) modules is a capping unit that addresses these concerns.

Case 2: Preventing Condensation on the Printhead

Adding moisture to the printhead capping unit environment to prevent drying is not suggested as it can lead to condensation on the printhead.

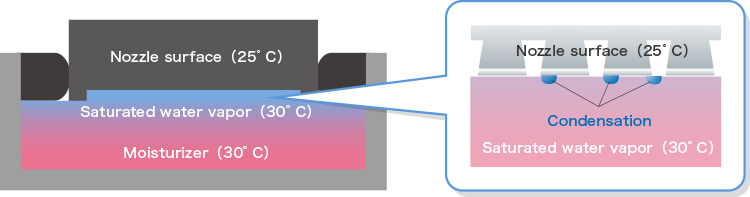

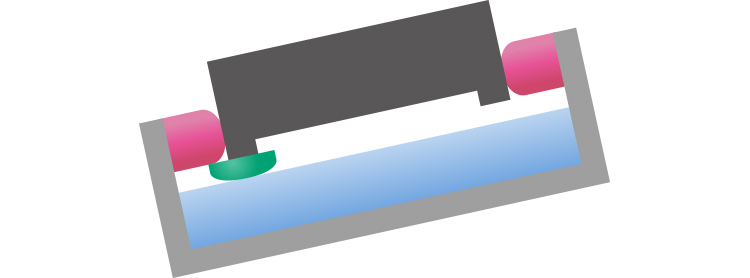

For example, consider a system where the ink is circulated by adjusting the temperature at 25ºC to change the viscosity of the ink in the printhead. If the temperature of the printer installation environment rises due to exhaust heat from the printer and the temperature of the moisturizer rises to 30°C (Fig. 5) condensation will likely form on the printhead.

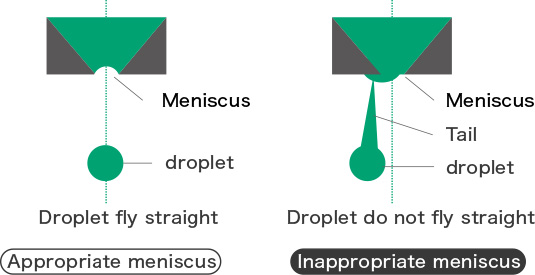

The temperature of the nozzle surface is lower than the ambient temperature, and if sealed tightly, can cause condensation to form on the nozzle surface. Condensation may form after only a few minutes of capping in certain environments. Any foreign matter on the nozzle surface, including condensation, will disturb the meniscus and adversely affect jetting as introduced in the previous article (Fig. 6).

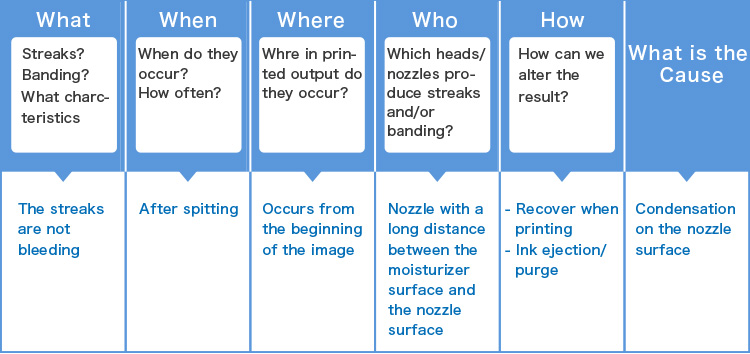

Streaks caused by condensation are summarized in Table 2 below. The evidence of streaks caused by condensation is smearing, which can be eliminated by printing or cleaning.

Table 2. Streaks caused by condensation

To prevent condensation on the nozzle surface, you can increase the temperature of the ink, but the ink tends to dry out near the nozzle. To prevent condensation on the nozzle surface and prevent ink from drying near the nozzle, it is essential to keep adequate humidity in the capping space. Controlling the temperature of the moisturizer in the cap is one of the most effective measures.

Case 3: Purged ink causes streaks

The third key function of the printhead capping unit is the ability to accept ink purged from the printhead. There are two common examples of streaks caused by discharged ink:

Floating ink droplets of a dummy jet adhere to the nozzle surface and streaks occur.

Ink may be ejected onto the cap to prevent the ink inside the nozzle from drying out.Under normal operations, ink is jetted from the printhead nozzles, while in contrast purged ink is absorbed by the moisturizer in the capping unit.

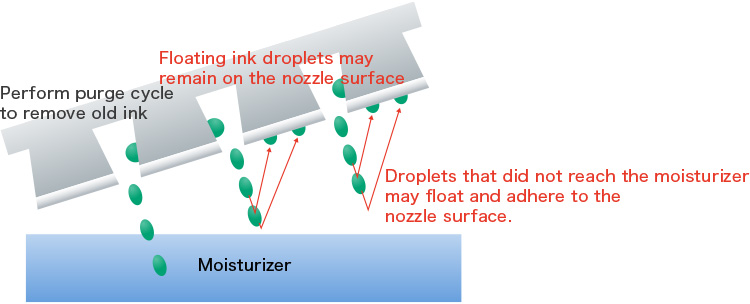

However, in some inkjet printers, the printbar is often tilted. (Fig. 7).

In a systems with a tilted printbar, the moisturizer surface inside the capping unit is horizontal, so the distance between the nozzle surface and the moisturizer surface varies depending on the location or the printheads (Fig. 8).

For this reason, purged ink from the nozzles near the moisturizer surface lands on the moisturizer. In contrast, the ink from the nozzles located far from the moisturizer does not land in the moisturizer and becomes floating ink droplets adhering to the nozzle surface.

The result is that the ink jetted to prevent the ink inside the nozzle from drying adheres to the nozzle surface and may cause a streak (Table 3).

Table 3. Example of streaks caused by floating ink droplets

Another option could be to bring the nozzle surface closer to the moisturizer surface or increase the discharge speed of the spitting. However, the resulting momentum of the ink may cause droplets of floating moisturizer, or the satellite of the ink may cause floating ink droplets.

The point of this measurement is to properly control the distance between the nozzle surface and the surface of the moisturizer. The FUJIFILM SAMBA® JPC capping unit module is designed to close the distance to the allowable amount of floating ink droplets while suppressing mechanical interference with the printhead.

Nozzle surface dries and streaks occur due to ejected ink.

Ink may eject from the nozzle when air bubbles enter the inside of the nozzle during system operation. Purged ink is usually absorbed by the moisturizer in the capping unit. However, as shown in the first example, if the printhead is tilted, then the purged ink will drip downward due to gravity and adheres to the sealant of the capping unit. If the ink then adheres to the seal and dries, the airtightness of the cap may deteriorate, causing the ink inside of the printhead to dry.

To resolve this problem, you must improve the relationship of the seal relative to the printhead position.

Other printhead storage issues

There are other potential causes of capping unit issues. If the above examples do not guide you to a solution, then consider how you store the printhead, how often you replenish the moisturizer, and the moisturizer materials.

Fujifilm believes that it can contribute to the development of the inkjet industry by supporting print system developers with its vast knowledge and data-driven experience gained through Fujifilm’s own print system development initiatives.

We will continue this series with an introduction to the challenges and examples of countermeasures.

Should you have any questions or concerns, please feel free to contact us using the inquiry form below.

FUJIFILM SAMBA® JPC: A set of inkjet components revolutionizing the speed of 1,200 dpi, high-resolution digital printer development.