Cleaning-related streaks: main points to check

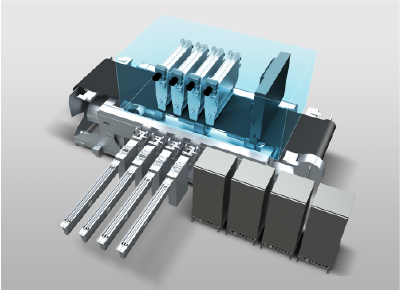

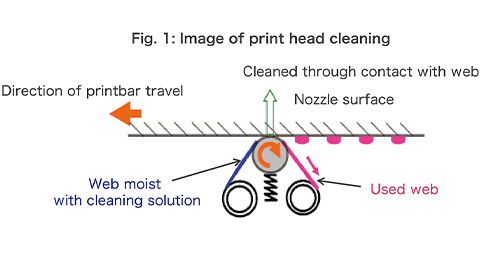

As shown in Fig. 1, the FUJIFILM JET PRESS inkjet printer employs a mechanism in which the surface of the printhead is cleaned by wiping with a roll of material (web) moistened with cleaning fluid.

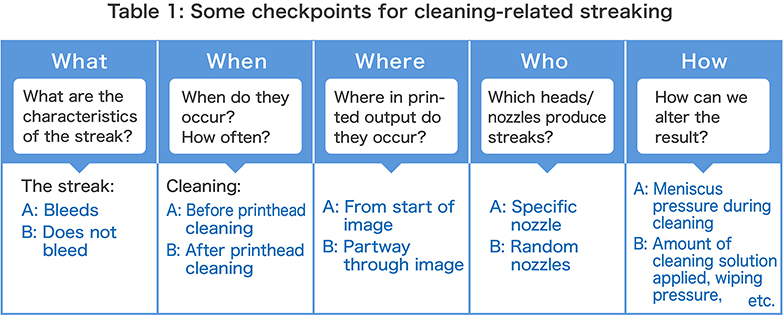

Table 1 below outlines the main checkpoints related to cleaning-related streaking phenomena that we actually employed during development of single-pass inkjet printers, including the FUJIFILM JET PRESS inkjet printer. As in the previous edition of this feature, we used a 4W/1H format.

When checking streaks related to cleaning, three factors: What, When, and Who (which printheads/nozzles), are particularly important. This is because cleaning-related streaks often show characteristics in these three areas. Let’s take a look at an actual case study that occurred during inkjet printer development, and how we approached countermeasures.

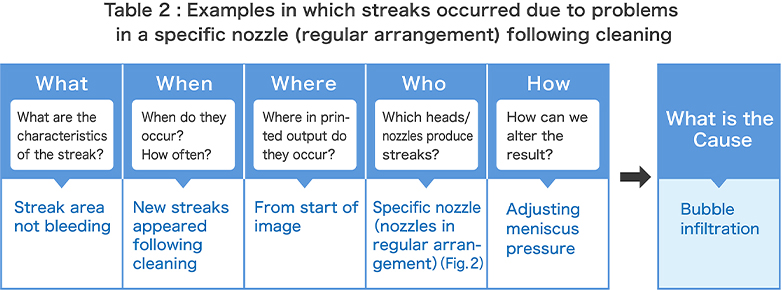

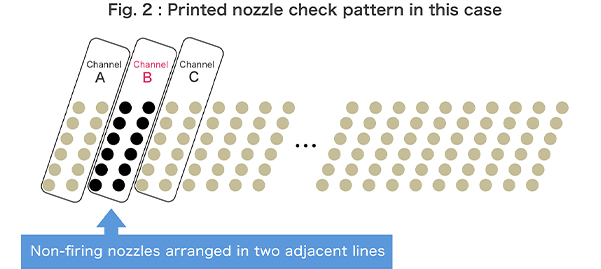

In this case, following cleaning (When) the nozzles aligned with the ink channel (Who) and caused a new streak in the printer output (What) (Fig. 2). Fig. 2 shows the printed nozzle check pattern at the time.

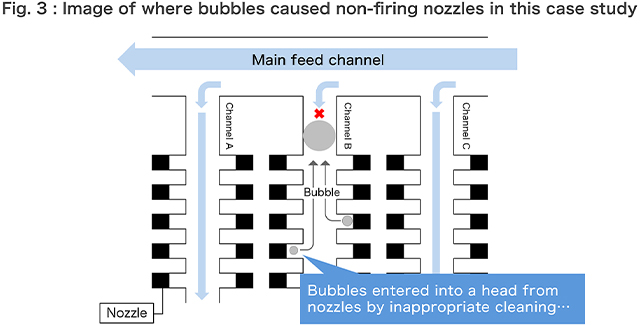

In this case, non-firing nozzles may be caused by contaminant moving along the print channel, such as bubbles in the printhead (Fig. 3).

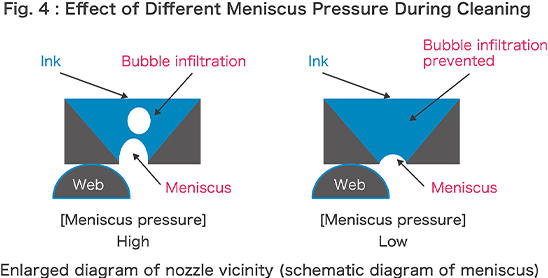

As the problem in this case occurred following cleaning, we can surmise that the nozzle surface of the printhead made contact in an inappropriate state during cleaning, leading to non-firing. The problem was solved through steps including adjusting the meniscus pressure during cleaning to make it more difficult for bubbles to be drawn into the nozzle interior (Fig. 4). However, it was not simply a matter of reducing the absolute meniscus pressure, as decreasing the meniscus pressure too far may make it easier for ink to be drawn out of the nozzle face. Finding the optimum meniscus pressure required iteration.

This example shows that in order to isolate and analyze the root cause of a problem occurring in nozzles, several hypotheses need to be established and verified.

The development of cleaning technology took several years, including adjusting the cleaning web

The cleaning web used in the FUJIFILM JET PRESS inkjet printer was designed specifically for this particular printer, and altering the functionality of the web alone requires the adjustment of a range of parameters, including the selection of the fiber. Optimizing the parameters, including combination with the web, took us several years of R&D to complete. This know-how has been thoroughly applied in the head cleaner of the FUJIFILM SAMBA® JET PRESS Components (JPC).

Through its work in developing the FUJIFILM JET PRESS inkjet printer, Fujifilm has amassed a wide range of knowledge and data for identifying causes and addressing problems. We can support your printer maintenance and usage and contribute to the development of the inkjet industry as a whole. Future installments in this series will address various, specific printer problems, such as those relating to streaks and banding, and outline examples of causes and measures for dealing with them. Look forward to reading more!

If you have questions, please do not hesitate to contact us via the inquiries form below.

FUJIFILM SAMBA® JPC: A set of inkjet components revolutionizing the speed of 1,200 dpi, high-resolution digital printer development.